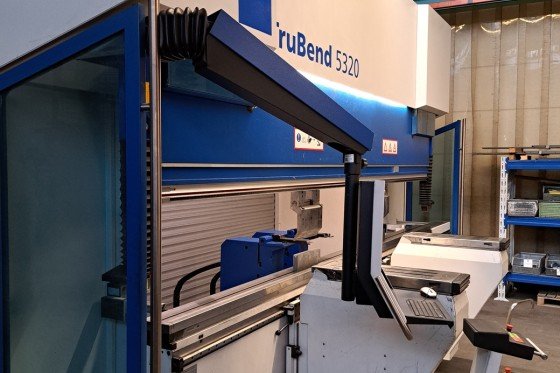

Standard configuration

Machine

⦁ Stable machine frame as all-steel construction

⦁ Ram, stress relief annealed

⦁ Spherical ram suspension, with ram tilt

⦁ Electro-hydraulic downstroking drive with 4-cylinder technology

⦁ Modern block hydraulics with control valves mounted on the cylinder

⦁ Electronic pressure balance

⦁ Measuring system: with centered glass scales and temperature compensation

⦁ Control panel: with LCD panel, footswitch für Emergency up, down and E-STOP

⦁ Oil cooler

⦁ Modern machine design

Backgauge system

⦁ Backgauge system 2-axes

⦁ 2 pieces back gauge fingers

Tool holder

⦁ Manual upper tool clamping

⦁ Hydraulic lower tool clamping

Crowning

⦁ Manual crowning

Lower Tool Adjustement

⦁ Pneumatic lower tool Adjustment, programmable

Safety

⦁ Standard Safety equipment: Emergency Stop button, manual roller shutter rear, protective panels, CE certificate

Control

⦁ TRUMPF TASC 6000

⦁ Network connection machine control

Additional equipment

Backgauge System

⦁ 6-axis backgauge System with switch cabinet cooling (air-air heat exchanger)

Tool holder

⦁ Hydraulic upper tool clamping

Crowning

⦁ CNC crowning

Lower tool shifting

⦁ Lower tool Adjustment: CNC controlled (I axis)

Safety device

⦁ BendGuard for 220mm/s.

⦁ Additional foot switch

Material handling

⦁ Bending aid first arm

⦁ Bending aid second arm

⦁ 4 x Table length extension

⦁ 2 x Table width extension

Additional options TruBend

⦁ Optical setup and positioning aid

⦁ Work area lighting rear

⦁ Work area lighting front

⦁ Preparation ACB

⦁ MobileControl